Leon Gurevich interviewed by the Manufacturing Engineering Magazine.

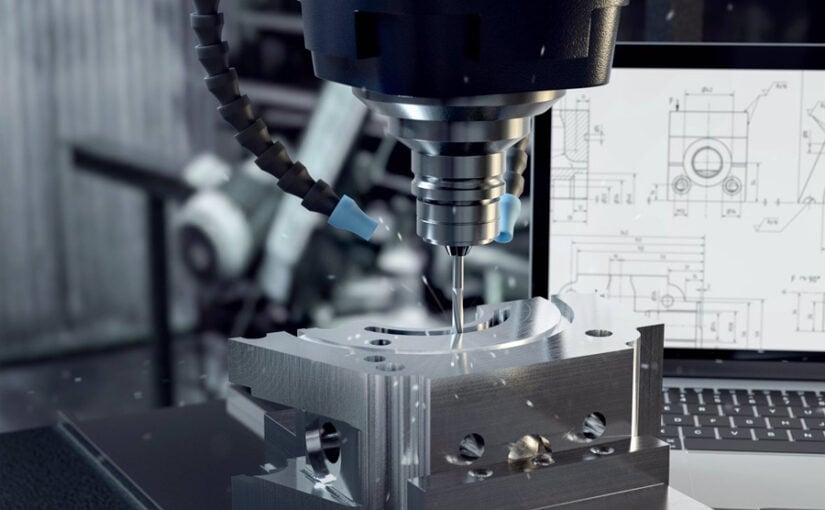

Rapid Development Services. provides Factory Automation Consulting Services for Medical Device Automation. The application of Robotics for assembly of Medical Devices, Leon Gurevich is interviewed by the Manufacturing Engineering Magazine, SME, Page 70.