Automation for the 21st century

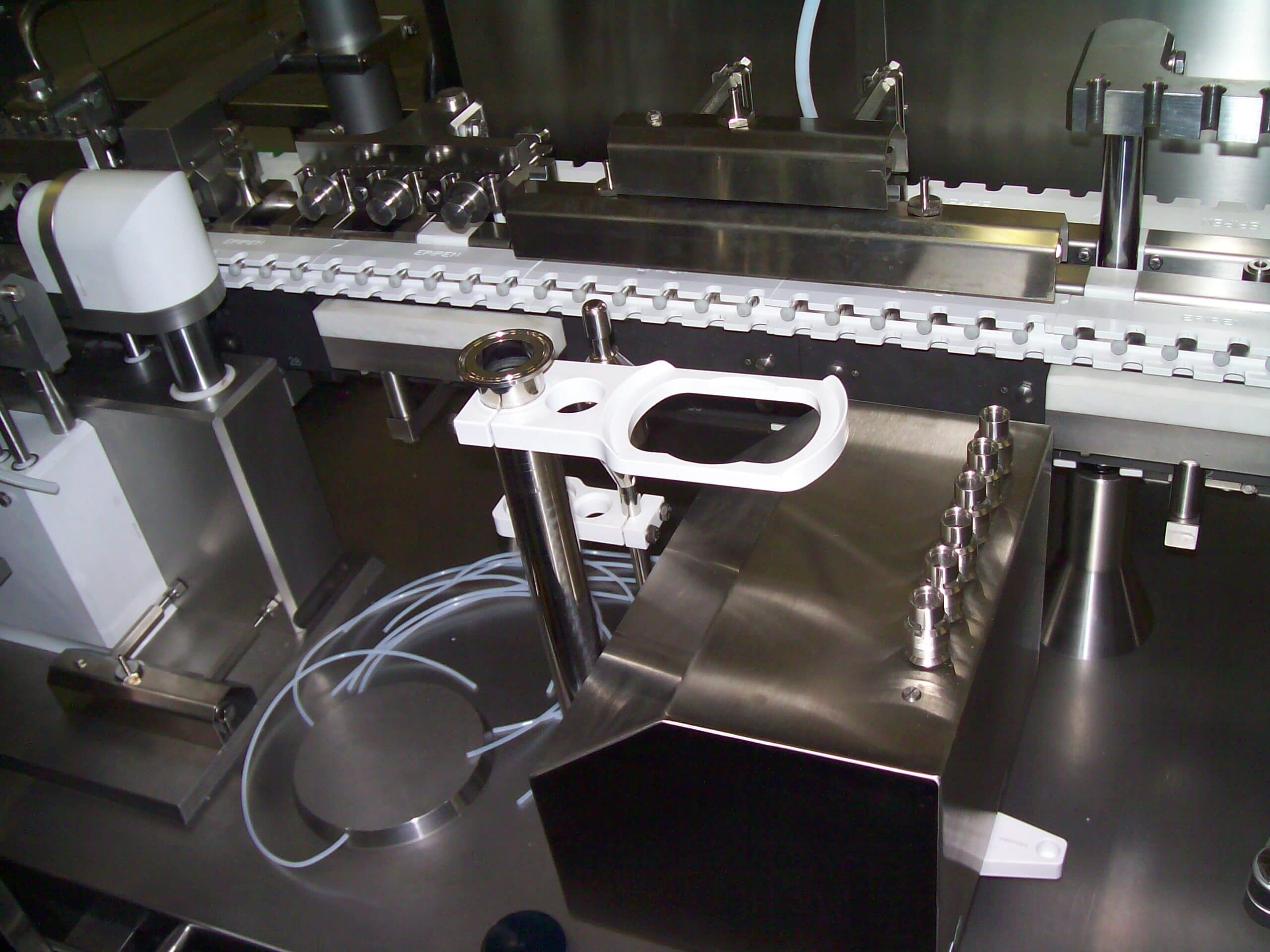

Rapid Development Services has designed and built systems for drug filling and packaging applications including vial filling, small bottle filling, pouching and syringe filling. The equipment designs meet class 10, 100 and 1,000 clean room applications that are aseptic using materials such as 304 and 316 stainless steels, Delrin and others. RDS has pioneered precision pump delivery systems for filling volume control of 0.01 mL with rates up to 200 parts per minute. Our history includes automatic systems for auto ejectors, medical swab kits, prefilled vials and syringes with automatic inspection/reject features.

RDS builds systems for filling, dispensing, inspecting, packaging, testing, and assembly of drug delivery devices. Materials include liquids, powders, and tablets. Data acquisition and record keeping meet the requirements of CFR 21 Part 11, cGMP and GAMP. We ensure high quality production and adhere to regulatory standards in the ever-changing pharmaceutical industry.

We have decades of experience in turnkey pharmaceutical equipment: