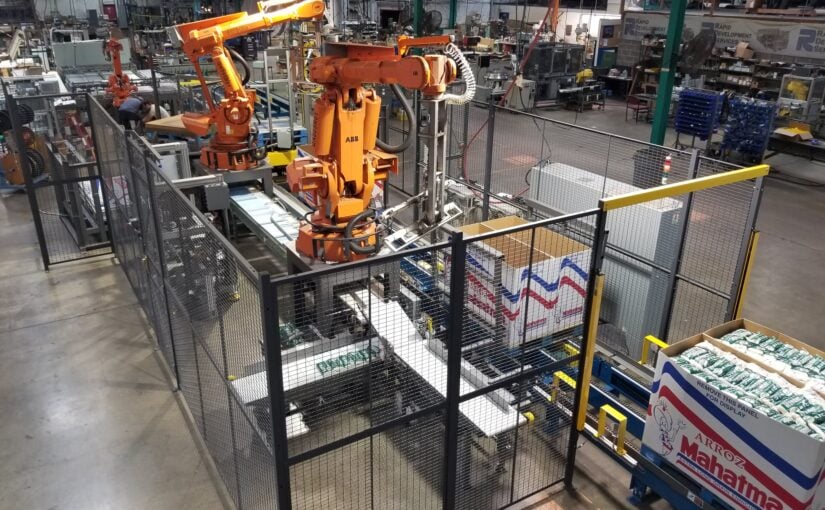

Centralized parts feeding to feed multiple production lines for assembly

Our latest technology starts with a large tote delivery and parts dumping into a centralized hopper. The parts get distributed by separate conveyors on demand to multiple feeding locations. These heavy duty conveyors hold up to 600 lbs of parts that can feed interlocking metal components. Belting for the conveyors prevents jams and are easily removable for parts maintenance. This technology eliminates the need for manual operators that were required to keep assembly lines full of product and down time from maintenance issues/jams on the line as well as reduces fork lift traffic.

Automation for the 21st century