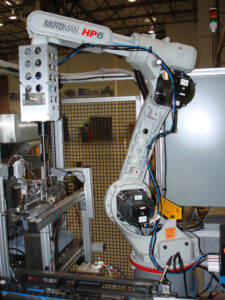

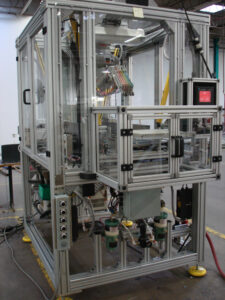

Rapid Development Services. introduced new method for robotic case packing of plastic bottles. The same system can be adjusted to stage multiple bottles in various arrays, pick and place bottles from 2 oz to 1.5 liters. This system uses 6-axis robot that can provide additional guiding inside the formed case. System can place up to 48 bottles per cycle at up to 150 bottles per minute overall rate. This system can pack bottles with pumps as well as bottles with difficult to handle features.

Automation for the 21st century