System Integration Services

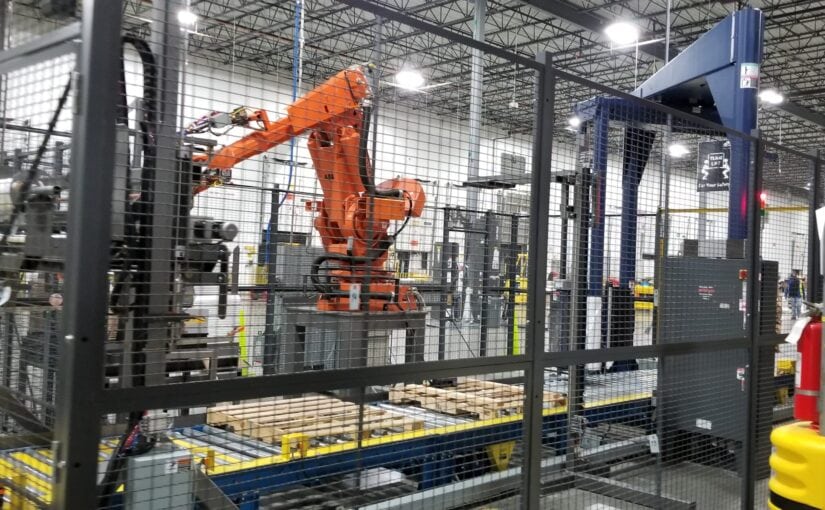

Rapid Development Services. is a Pharmaceutical Line System Integrator, providing complete line installations. The typical equipment may include bottle unscrambling, liquid or tablet filling, bottle capping and torque, bottle weighing, sealing, re-torque, bottle labeling, bottle banding, carton erecting and bottle packing, case forming, case packing, case labeling, case weighing and case palletizing.

Pharmaceutical Equipment Line Integration Services.

Bottle filling: Liquid or Tablets

Services:

– Review of Products drawings and Products Specifications

– Review of Process Steps and Machine requirements

– Specifying standard or custom machinery

– Providing price quotes for machinery for the line

– Conveyor selection and integration

– Standard machines and conveyors procurement

– Delivery of all equipment to the Integrator Plant

– Uncrating, positioning, wiring and check out of machinery

– Conveyor alignment

– Fabrication of railing and guiding tooling

– Fabrication and mounting of profiled splash type aseptic Wire-way.

– Centralized Control Panel with a single sealed electrical and piping drop.

– Electrical wiring from the panel to the line

– Compressed air piping thru the wire-way.

– Water line piping.

– Nitrogen line piping

– Centralized Variable speed drives installation and wiring

– Power distribution disconnects and control motor starting for the line equipment.

– Bottles Spacing wheel installation and wiring

– Sensors installation and wiring

– Equipment start up and adjustments

– Line speed coordination

– Back end Packaging equipment set up and testing.

– Line start up services

– Validation support services.

– Start up and testing

– Change over for different size bottles

– Line Disassembly and crating

– Line shipment to the Customer plant

– Equipment rigging and placement at the customer plant

– Equipment reassembly and wiring

– Equipment check out and start up.

– Validation support

– Production support