Automation for the 21st century

Two uniquely different cases show how an adept system integrator can build customized equipment and lines not available off the shelf

Increasing production speed while keeping rejects low and quality consistent—and maintaining food safety—is the goal of every food and beverage processor. Today, many food processors look toward automation to provide the solutions needed to attain the necessary throughput to be competitive.

Problem is, while processors can buy off-the-shelf equipment to tackle a variety of automation applications, orchestrating all this equipment to tackle the job from start to finish can eat up a lot of engineering time.

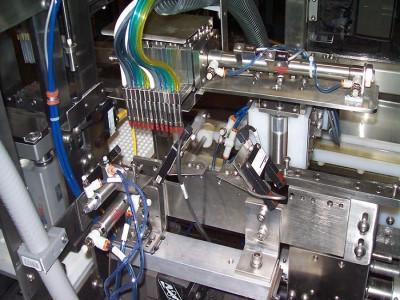

In this article two food processors—one with an existing facility and one with a new plant—needed production lines designed, built and completed as quickly as possible. Both called upon Rapid Development Services (RDS) to evaluate their projects and come up with an automated solution (including robotics). Both projects included novel inventions to accomplish their respective projects.

Changeover time was critical and Gurevich reports, “The system exceeded customer’s requirements, to have a change over time of less than 15 minutes.” The design had universal tooling and programming, allowing seamless conversion from one size bag product to another without mechanical changes.

The application required new solutions in several areas, says Gurevich, which included: