RDS, Inc. has been actively involved in developing customized packaging automation since 1983. The application of our vast machine design experience, combined with our in depth knowledge of packaging materials, package design, packaging line layout and equipment position RDS as a turnkey source for packaging automation. Our packaging and material handling systems are currently utilized by these industries: Food and Beverage, Electronic, Medical Device, Pharmaceutical Consumer Products and Cosmetic. RDS is familiar with all regulatory agency requirements influencing equipment design for these industries including: OSHA, USDA, NEC, NEMA, FDA and GMP. We work closely with our customers to assure that equipment validation, factory acceptance and site installation are a seamless process.

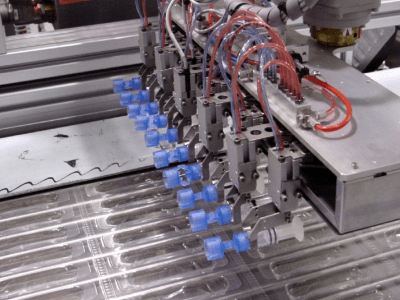

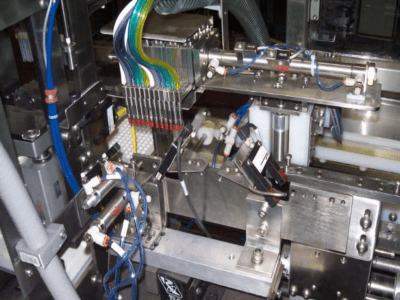

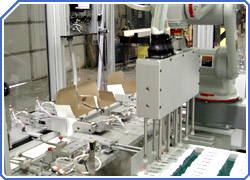

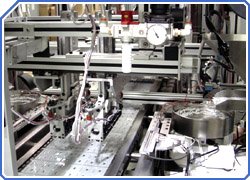

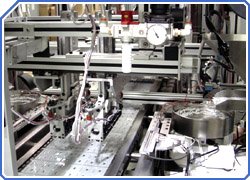

RDS’s approach to the packaging industry is to provide robotic solutions that are more cost effective and offer higher flexibility than traditional standard or custom dedicated equipment. Our extensive experience, encompassing several industries, provides us with unique knowledge of product and package compatibility. This knowledge is reflected by the number of successful packaging automation projects we have implemented. RDS designs and builds turnkey solutions to your automation needs.

- Cartoning Systems

- Puck and Depuck

- Robotic Palletizing Systems

- Barrel Lifters

- Case Packing

- Stretch Wrapping

- Package Vision Inspection

- Robotic Loading Packing

Rapid Development Services. is a member of PMMI